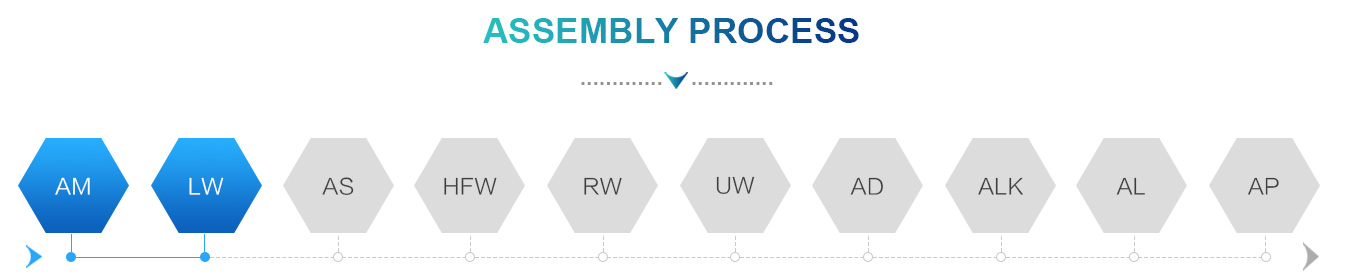

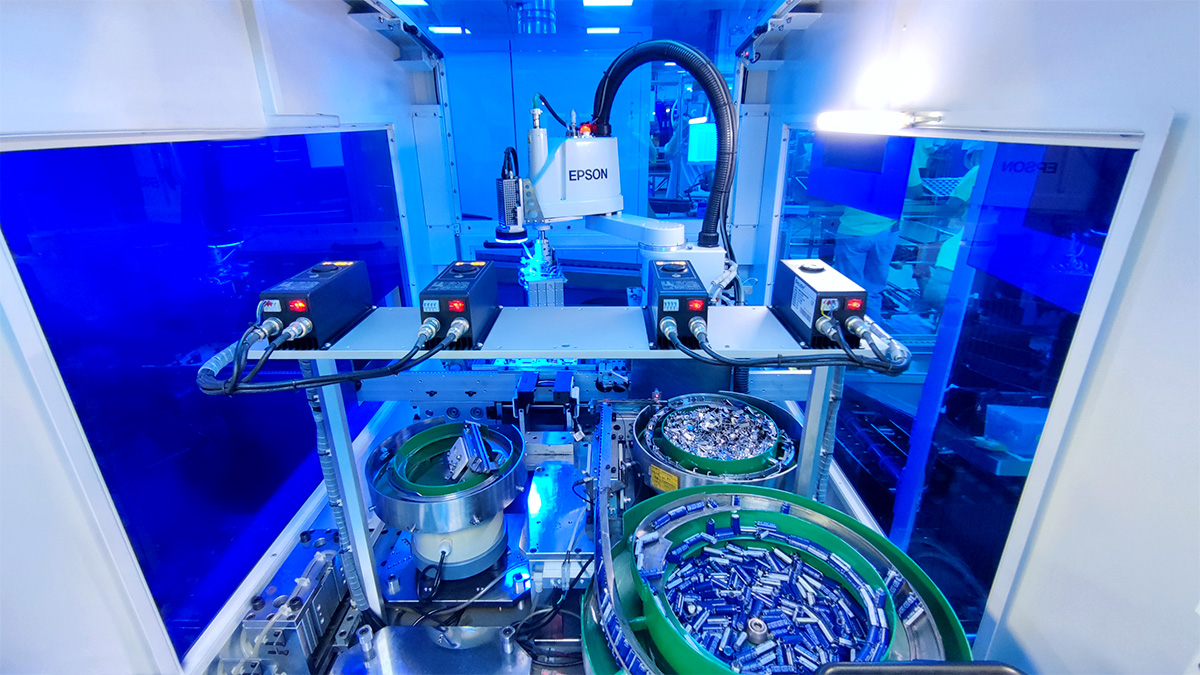

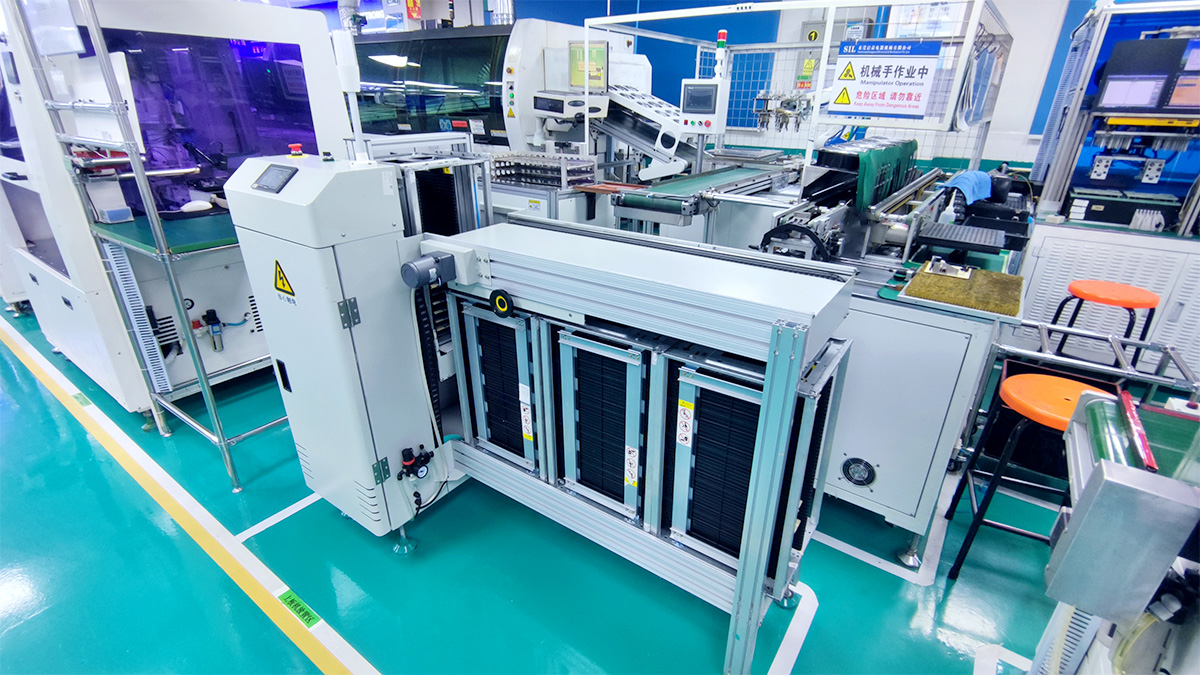

Sunstrong boasts a robust infrastructure of over 100 Lean assembly production lines and a skilled workforce of over 2,000 operators. Our advanced automation equipment, developed and manufactured in-house, enables us to meet the customized product demands of our customers effectively. With the implementation of an MES traceability system, we ensure meticulous quality control and provide comprehensive product tracking capabilities. Our commitment to excellence ensures that we deliver exceptional quality and tailored solutions to our valued clients.

“Box build,” also known as systems integration, is the complete assembly of a customer’s finished product. The process goes beyond the production of printed circuit boards (PCBs), extending to electromechanical assembly that includes enclosure fabrication, installation and routing of cables or wire harnesses, and installation of sub-assemblies and components. The box can refer to a PCB Assembly (PCBA) in a cabinet full of wires, a small enclosure, or a complex, fully integrated electro-mechanical system with pneumatics and electronics.

SUNSTRONG has extensive experience in the full lifecycle of manufacturing electronic products from a printed circuit assembly, through sub-assembly, and on to their final product states.

At EMS Solutions, we free our clients up to concentrate on other aspects of their businesses. Our services help companies reduce their internal capital and other resource investment requirements.

EMS Solutions is known for PCB solutions. These include the following components of box build assembly:

Product assembly

System-level assembly

Sub-level product assembly

Packaging and labeling

Testing

Software loading and product configuration

Warehousing and traceability